LASER4SURF

LASER FOR mass production of functionalised metallic SURFaces

Objective of the project

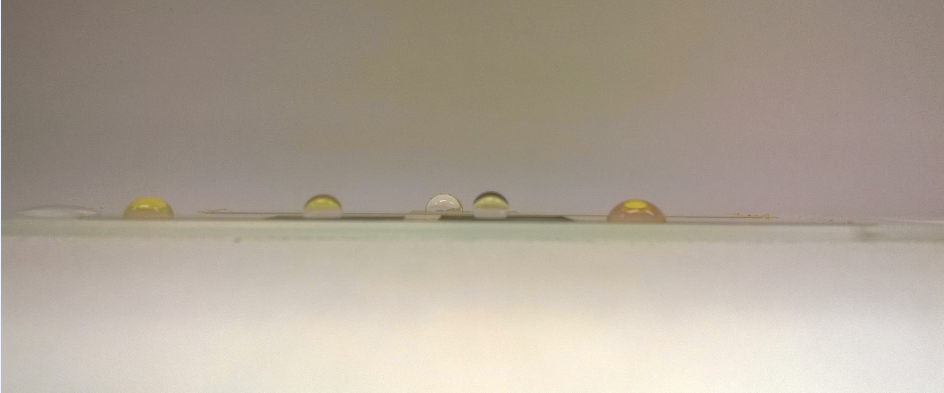

The main goal of the LASER4SURF project is to develop a laser based solution for the functionalization of metallic surfaces with textures ~1μm or less on mass production. This solution will be based on surface functionalization with ultrashort pulses via Laser Induced Periodic Surface Structures (LIPSS).

The LASER4SURF project will develop a Laser Texturing Prototype to overcome the current barriers for the LIPSS technique to reach mass production, achieving a production rate of 0.1 min/cm2. This prototype will need:

- high process time for large 3D pieces

- inline inspection methods

- modelling tools for parameter selection.

The development will be focused on the three main steps of the Laser texturing value chain:

- Laser technology/equipment. To generate different LIPSS pattern sizes with multiple orientations, LASER4SURF will develop an easy to integrate and control, compact and low cost optical module.

- In-line inspection tool. A whole optical measurement system based on diffractometry technology will be integrate with the laser equipment including hardware and software in order to be able to monitor all different nano properties from the functionalised surfaces.

- Simulation tool that will show automatically the process parameters required to obtain the desired functionality for a specific material. The simulation tool will automatically transfer the optimum laser parameters to the LIPSS equipment in order to configure it for the desired pattern.

The project will combine the developments in an all-in-one solution, that will be validated by three different use case products that represent a broad range of the main industries, metal alloys used and required functionalities.

The LASER4SURF project will be developed by a well-balanced consortium that brings together 8 partners: 3 technology developers (CEIT, MULTITEL and VISUM), an integrator of the solutions (LASEA), three industrial partners (FAGOR, RESCOLL and CIC) and a dissemination partner (ESCI).

Contribution of Multitel

Due to its vast experience in ultrashort pulse lasers, in LASER4SURF project, MULTITEL will be addressing the beam shaping issues. Besides, it will collaborate in the integration of the optical module into the final texturing system.

Applications

- Medical components

- Advanced batteries

- Linear encoders